Prototype Mk-0

Why Mk-0?

Because our MVP needs to be scalable to a point of universal utility. With the proof of concept crystalized (If you pardon the pun), the road to the ultimately adaptable Piezoelectric Unit doesn’t seem that long anymore. With funding and the upcoming iterations secured, we have the luxury of taking it slow, yet accelerating.

Progress Tracker

Yield Thresholds ✅

Current Equalizer ✅

Array Fitting✅

Crystal Composit ✅

Stress-Response Ratio✅

Casing Conductivity ✅

Board Layouts ✅

Controller Compatibility✅

Form Factor Constraint✅

Combination Modelling ✅

Serial Interface Port ✅

SaaS Base Code ✅

April 1st, 2025

First Module success:

Testing Begins.

- KCM Tech

April 3rd, 2025

✅ 1. Yield Thresholds

Complete – PSCB Mk-0 consistently reaches operational voltage under minimal stress. Yield per cycle confirmation across 10-module simulations.

✅ 2. Current Equalizer

Complete – Internal balancing verified. Voltage spikes were mechanically suppressed across array strings; the passive equalizer successful at sub-1% deviation across tests.

April 4th, 2025

✅ 3. Array Fitting

Complete – Modular 1 Unit frame & attachments.

For Mk-I: Scaled array design fits within Mk-1 dimensions. Pathways for 6× and 12× module integration confirmed on a 2-layered substrate or conductive mold.

✅ 4. Crystal Composit

Complete – Crystaline-Ceramics on CU plating.

For Mk-I: Ceramics selection narrowed to optimal PZT-ZnO hybrids. Material screening validated composite resilience and piezo coefficient performance.

April 10th, 2025

✅ 5. Stress-Response Ratio

Complete – Minimum input force-to-output ratio mapped. Micro-vibration harvesting is confirmed to be viable for passive environments (e.g. body motion, drone chassis).

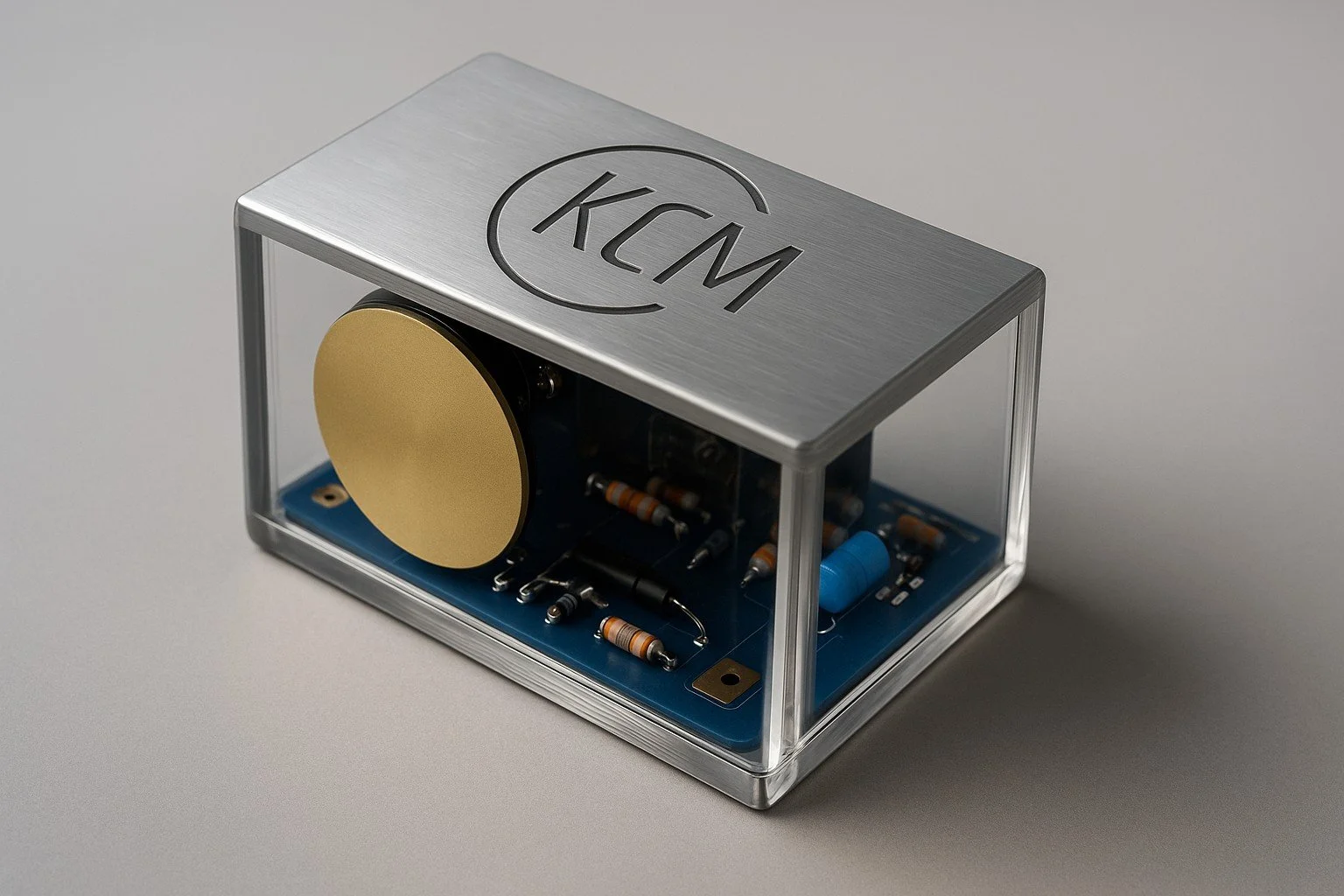

✅ 6. Casing Conductivity

Complete – Stainless Steel metafold with Acrylic Viewports for Mk-0.

For Mk-I: Hermetically sealed frame using carbon-fiber thermoplastic achieves thermal neutrality + low EMI emission. Stainless composite pass-through tested.

April 18th, 2025

✅ 7. Board Layouts

Complete -The circuit layout proved simpler than anticipated. All critical pathways scaled cleanly across 3× and 5× configurations. No signal bleed or voltage distortion observed. This confirms that board-level scaling is not only possible—it’s elegantly straightforward.

✅8. Controller Compatibility

Complete - We’ve achieved a fully mechanical, controller-free version. Energy routing occurs without microcontroller mediation under standard load. Scaling code has been adjusted for hybrid setups, but the standalone mode already works cleanly.

✅9. Form Factor Constraints

Complete - The design compressed again, beyond projections. The materials naturally support miniaturization without performance decay. Layer density, weight, and energy per cubic cm now clearly prove wearable integration thresholds.

April 28th, 2025

✅10. Combination Modelling

Material Science Combination Modelling has officially crossed into classified territory following early-stage sensitivity review. Accordingly, detailed disclosures on our internal simulations will be deferred until end-of-year clearance cycles conclude. On the public side: Casing Architecture been finalized. We expect full publication of the casing design strategies—balancing mechanical resilience, stress distribution, and energy yield maximization—before the end of the year.

✅ 11. Serial Interface Port

As of this month, legacy battery charging integration has been successfully proven. We have confirmed that PSCB energy harvesting arrays can now natively charge standard rechargeable battery types, including lithium-ion cells, via a regulated serial interface.

Smartphone and USB-C hardware compatibility has been demonstrated under lab conditions, opening a new pathway toward seamless retrofit applications.

(Yes, the future might include your devices quietly charging themselves—without you noticing.)

✅ 12. SaaS Base Code

The Arduino-compatible base code for PSCB module management is now complete and undergoing early-stage external validation. The codebase allows real-time energy harvesting data logging, charge state tracking, and basic adaptive stress-response calibration. Initial internal testing is live, with field-ready firmware iterations scheduled to begin by early summer. We are treating the PSCB SaaS Layer as a critical bridge between passive energy generation and intelligent active device management.